From fossil-fuel district heating to climate-friendly neighborhood solution

Replacing fossil fuels and switching to more sustainable forms of heating is a central element of European climate policy. Dimplex is demonstrating how this can be implemented quickly, flexibly and highly efficiently in sparsely populated areas by means of an individually planned system solution with heat pumps that is tailored to local conditions: an entire residential area was converted to a decentralized “green” local heating network that is fed by three highly efficient Dimplex heat pumps.

Like millions of people in Denmark, most households in the town of Slotsbjergby, which has a population of 1,100, are connected to a district heating network – in this case a gas-fired one – in the south of the country. In order to ensure a climate-friendly energy supply there in the future, a local residential area was to be converted to an efficient renewable heating technology. The requirement was to modernize the entire district, with three existing building complexes and a total of 47 apartments, in an energy-efficient manner and to disconnect it from the fossil-fuel-based district heating supply. The particular challenge of the project was that due to the spatial conditions, there was no possibility of accommodating the hydraulics inside the buildings during the retrofitting.

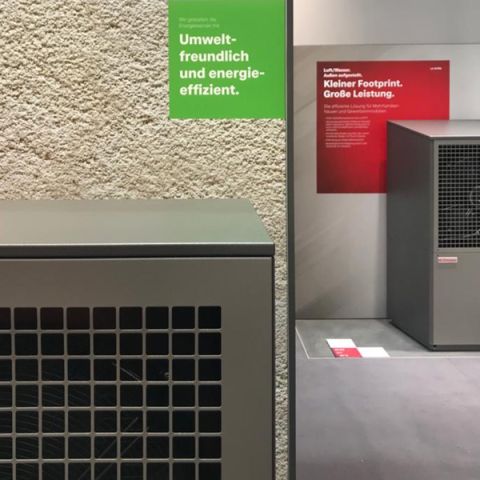

Climate-friendly large heat pump with R290

Dimplex developed a system solution tailored to the individual requirements, in which three Dimplex System C LA 60P-TUR heat pumps were used in combination with a containerized hydraulic station as a plug & play concept. As a flexibly installable reversible heat pump that is specially designed for large-scale projects, such as apartment buildings or office buildings, the LA 60P-TUR can cover a building's heating needs of up to 60 kW. With two compressors that always work in a demand-oriented and cost-optimized manner, as well as speed-controlled fans and a sound-optimized compressor chamber, it meets the highest requirements for sound and efficiency. With a COP of 4.9 in heating mode, the LA 60P-TUR achieves a high seasonal performance factor – and that with an inlet temperature of up to 64 °C.

Another advantage: as one of the few heat pump models in its power class, it is operated with the natural and environmentally friendly refrigerant R290, so that the Dimplex LA 60P-TUR was the optimal choice for this ecological and future-oriented modernization project not only because of its efficiency, but also because of its low GWP value.

Customized container with hydraulic station

While the three System C heat pumps from Dimplex, placed next to each other at a central location in the vicinity of the residential buildings, form the “heart” of the new climate-friendly local heating network, the “brain” is right next door: a simple container that at first glance could be mistaken for a storage shed or a bicycle garage reveals a highly technical interior on closer inspection. The compact area of just 5 x 2.5 meters houses the complete heating system of the plant.

“We had to find a way to move all the technology outside, because there was no room for it inside the residential building,” says planner Maik Heydrich, Key Account Manager Engineered Systems/ESE at Dimplex, describing the special challenge of this modernization. The customized solution: a ready-to-plug-in container that contains a comprehensive hydraulic station – including a complex control cabinet for load supply from three systems, heating circuit distributors for three heating circuits, circulation pumps and a 1000-liter buffer storage tank. The complete system was delivered as a plug & play concept, i.e. all the components, which were matched to each other, were already pre-configured so that the new heating network could be put into operation within a day. After the modernization, the hot water supply is still provided decentrally by electricity.

Only ten months from initial contact to commissioning

The individually planned hydraulic container is not only a clever solution for the space problem, but also has other advantages: it enables uncomplicated maintenance, thus ensuring smooth system operation and maximum safety – right from the planning stage. In the modernization project in Slotsbjergby, just ten months passed between initial contact and commissioning. This rapid turnaround was possible, on the one hand, thanks to Dimplex's expertise in customized system solutions and many years of experience in large-scale plants. On the other hand, however, it was also due to the high degree of flexibility in the planning. “While the new pipes were still being laid in Denmark, we were already planning the container,” says Maik Heydrich, describing the highly agile approach taken in this project. From the device configuration to the safety concept – the entire planning work for the complex hydraulic container was carried out completely independently of the work on site.

All that remained was to take the heat pumps and the plug-in container to their destination and connect them – a quick and easy task thanks to the plug-and-play concept. “Delivery took significantly longer than the commissioning,” says Maik Heydrich, highlighting the quick and uncomplicated processes. Dimplex provided support from the outset with the precise adjustment of the hydraulic components. The demand-based control via six power levels using the intelligent Dimplex Master control allows for a cascading of up to 14 heat pumps. Compatibility with interfaces and cloud connections via APIs offers the option of monitoring and remote access.

Achieving climate neutrality with customized system solutions

The new system has already mastered its first heating period, during which the Dimplex heat pump system performed smoothly and efficiently, fully meeting all expectations. The switch from the fossil-fuel district heating network to the climate-friendly neighborhood solution is already a success story in Slotsbjergby. And the project makes one thing clear: individual system solutions in which the heat pump can be used flexibly and highly efficiently for large-scale projects are an important step on the road to sustainable

Contact:

Anja Fischer, Director Marketing Heating & Ventilation

E [email protected]

M +49 151 599 51 260